These are the build instructions for the Simon Says game kit v1.0 and 1.5. While this kit is for beginners, these instructions assume that the user has a basic knowledge of soldering. If you do not know how to solder, then check out this great guide by Sparkfun before continuing.

Note: These instructions are for both v1.0 and v1.5 boards. They are both the same functionally, the only difference being the v1.5 boards have better labeling for the components. All boards are labeled with “Simon Says” followed by a version number. If you are looking for instructions for v2,0 boards, look here.

Also, the game does make repetitive beeping noises by default. However, there is a silent mode. To enable silent mode, just hold the button below the red LED while turning the game on.

———

The following tools are used in this tutorial:

- Soldering iron (required)

- Solder (required)

- Wire cutters (required)

- Desktop vice (optional, but very, very useful).

———

First, ensure that you have all of the pieces of your kit. The kit includes:

- 1x Simon Says PCB

- 1x 2xAAA or AA Battery holder (batteries not included)

- 1x ATtiny44A (pre-programmed)

- 1x 14-pin socket

- 4x Tactile pushbuttons

- 4x Bright LEDs (multiple colours – red, green, blue, and yellow)

- 1x Red power LED

- 1x Piezo buzzer

- 5x 10K ohm resistors

- 4x 680 ohm resistors

———

Click the photos for higher-resolution versions.

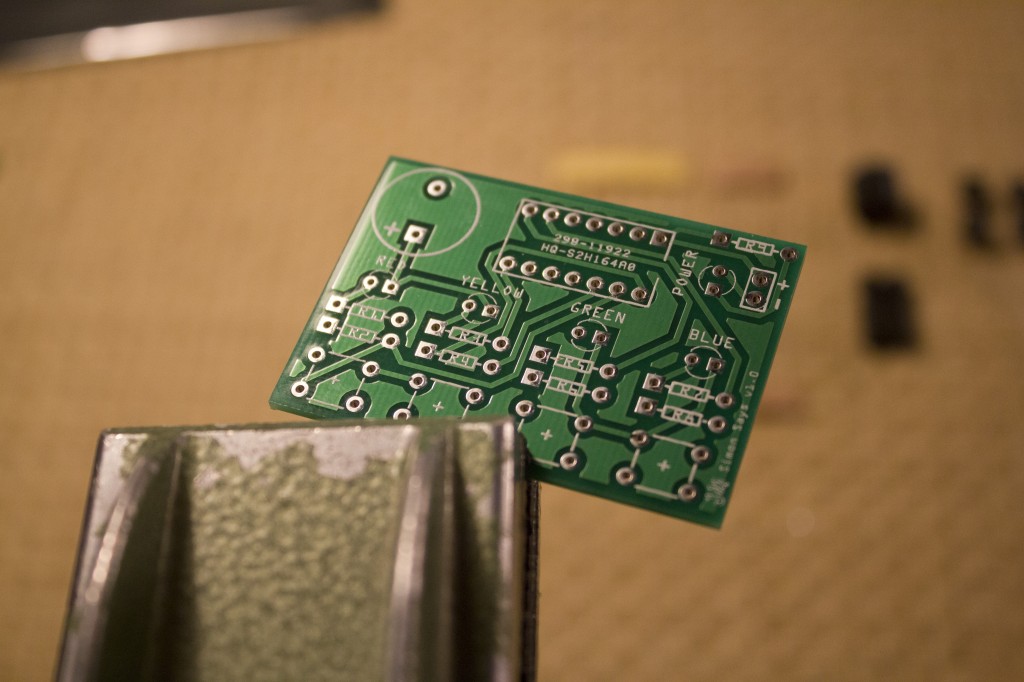

Start by placing your PCB into a desktop vice with the silkscreen side up.

When soldering to a PCB, it is a good idea to start with low-profile components, working your way up to the ‘taller’ components.

We are going to start by adding the 10K ohm resistors. They will fit into the R2, R4, R6, R7, and R8 spots. The resistors in your kit may be labeled, however they can also be identified by the colour bands – brown, black, black, red, brown. Another way of identifying them is by using a multimeter to measure their resistance.

Start by bending the leads on your resistors at a 90 degree angle. Try and leave a bit of a wide bend like in the photo below. This will help the resistors stay in place a little better when the PCB is upside-down.

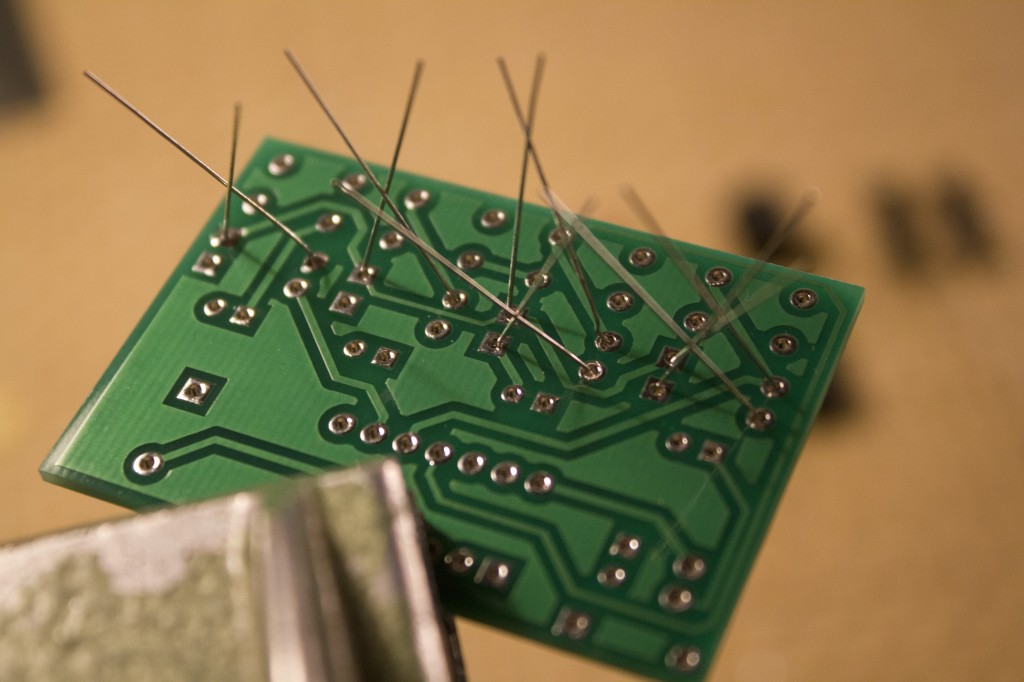

Insert the first resistor. Orientation is not important, as resistors do not have polarity, so don’t worry about inserting it “backwards.” If it is loose-fitting, then bend the leads on the other side so it can stay in place without falling out.

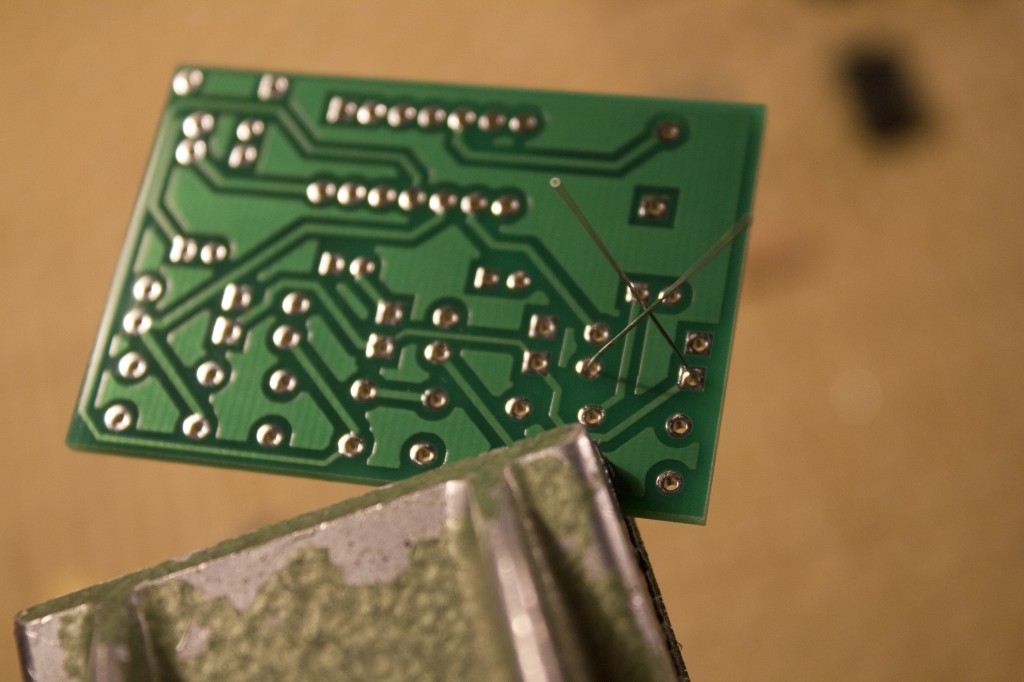

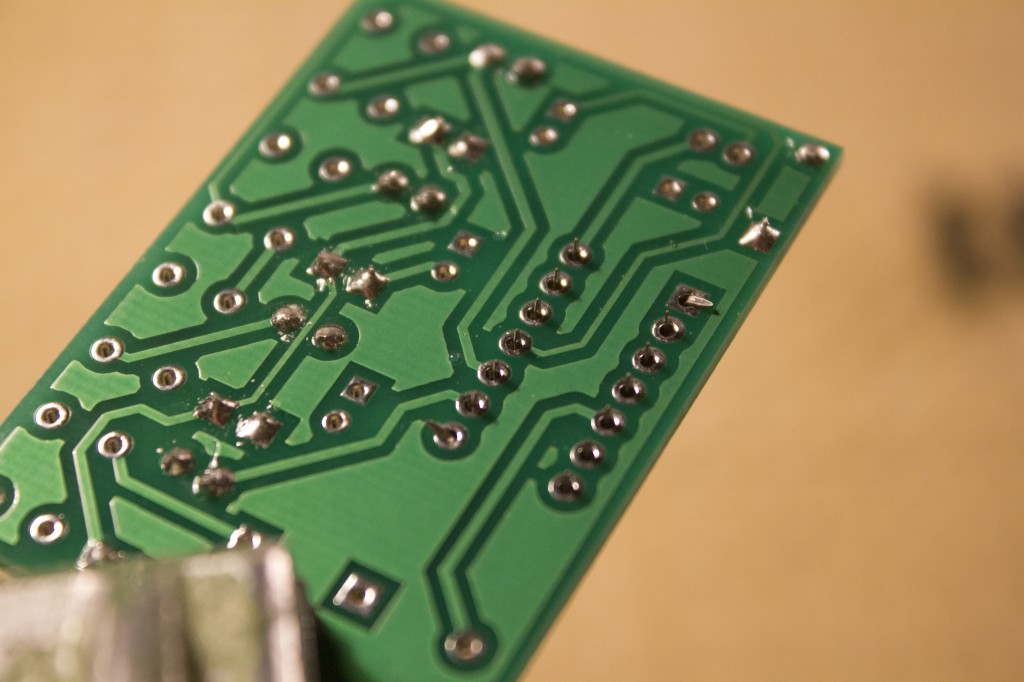

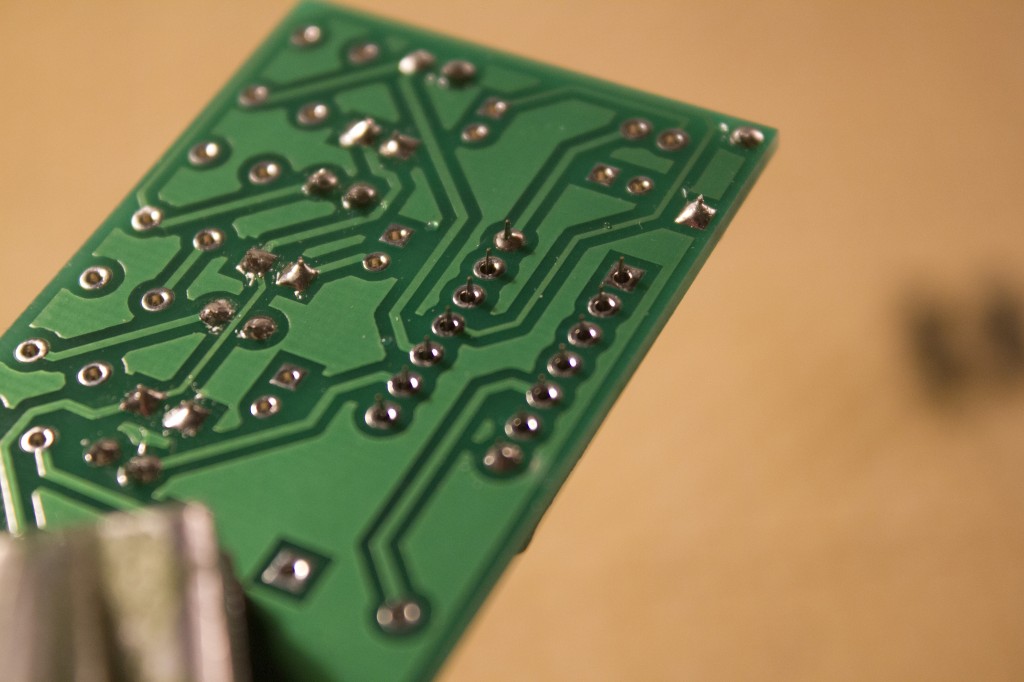

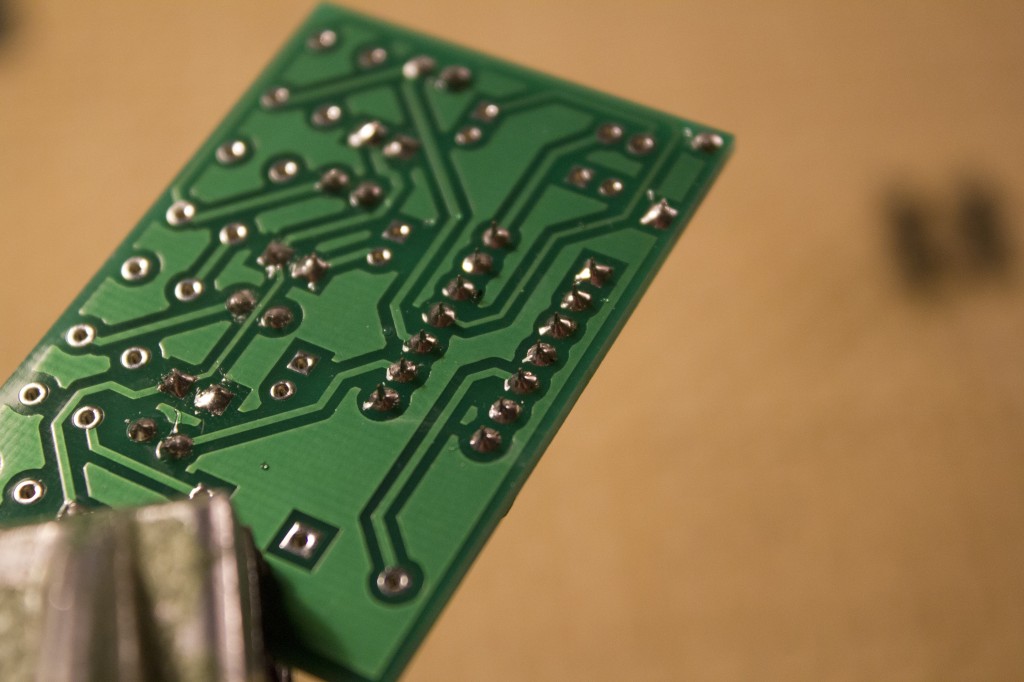

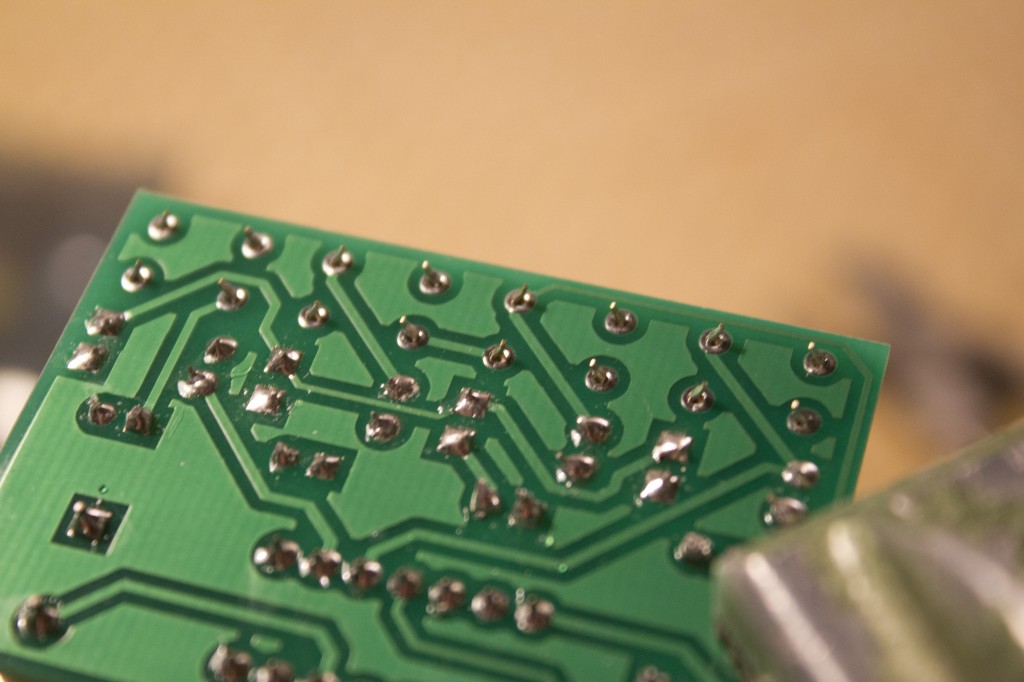

Remove the PCB from the vice and flip it over. If you can’t get your components to stay in place when upside down, try bending the leads. If that still doesn’t do the trick, then use a little bit of tape to hold them to the board. Solder the resistor to the board, and repeat this process for the rest of the 10K ohm resistors in spots R4, R5, R6, R7, and R8. When you are done, it should look like this.

Now we need to clip the excess leads. Using wire cutters, cut the excess wire off of the resistors as as close to the top of the solder joint as you can. Note that excess wire may go flying into your face when clipped, so either wear safety goggles, or hold onto the excess wire while you snip it. You should continue to cut the excess wire off of components as you go along.

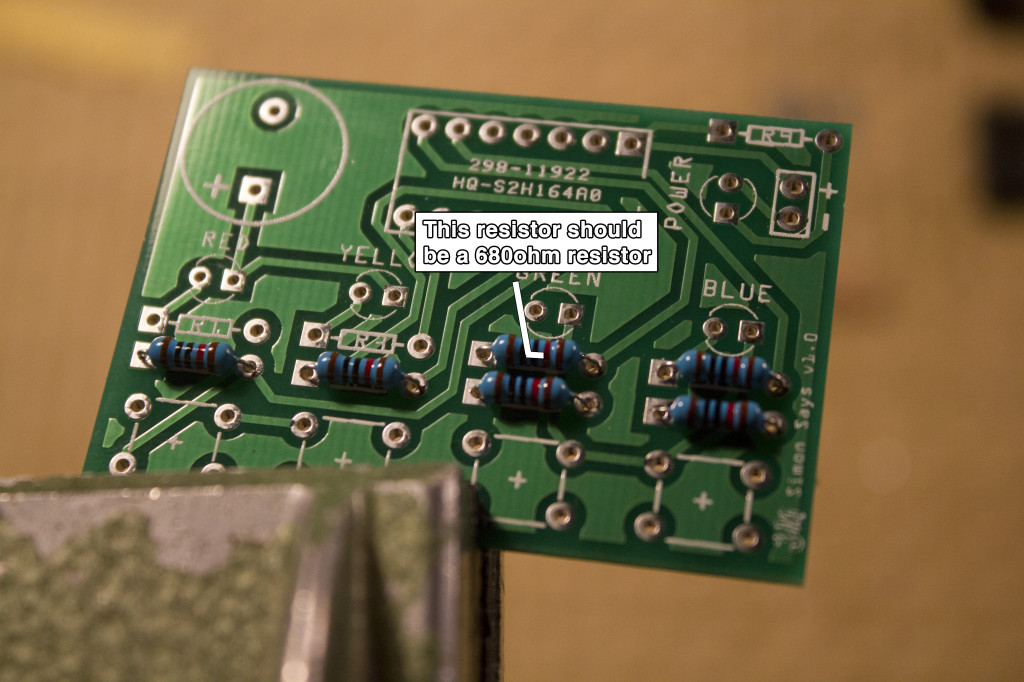

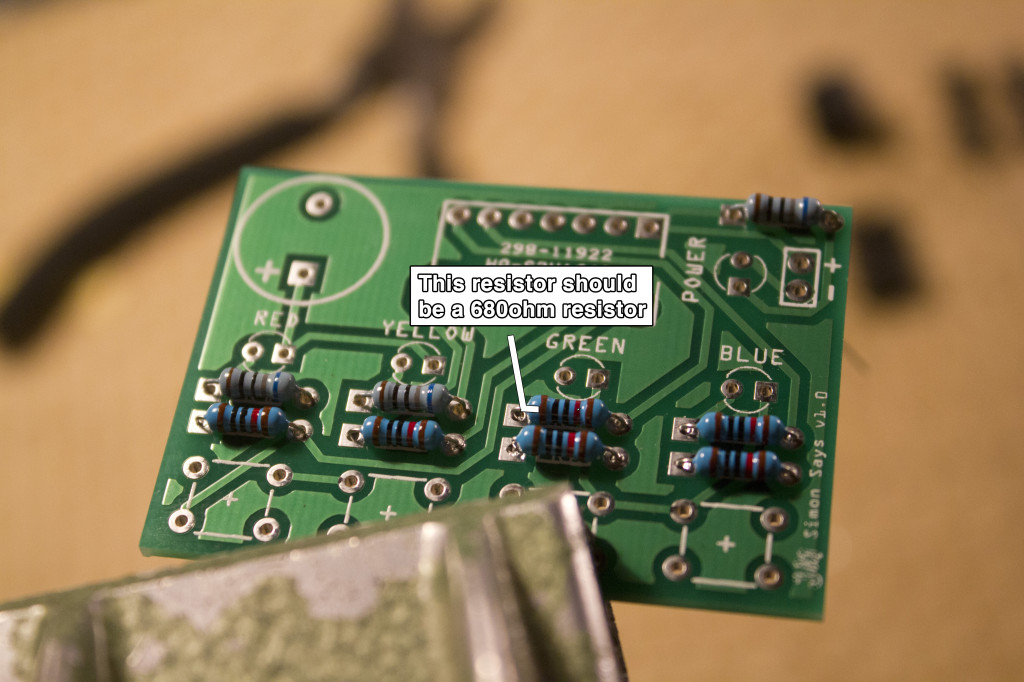

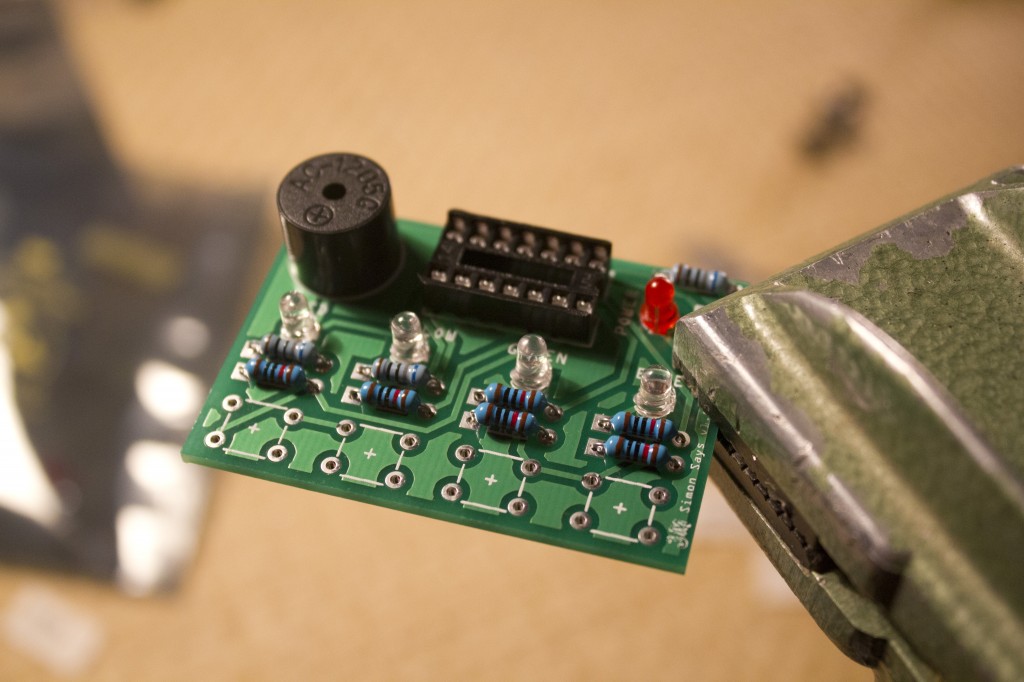

We are now going to add the 680 ohm resistors. They will fit into the R1, R3, R5, and R9 slots. Insert them and solder them in place.

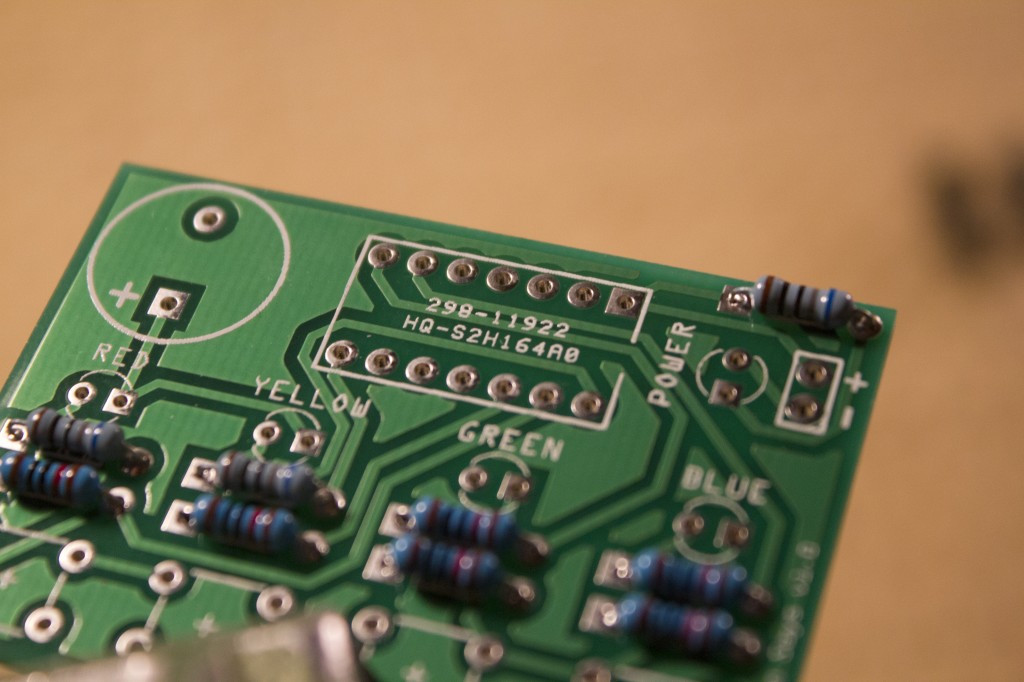

Up next is the IC socket. On the PCB, it is indicated by the rectangular box with a serial number.

When inserting the socket, note the small half-circular cutout should align with the gap in the silkscreen (or the half-circle on v1.5 boards). See the photo below for clarification.

To get the socket to stay in place when flipped over, bend the pins on two opposing corners.

Then, solder another pair of opposing corners. Un-bend the pins and solder the rest.

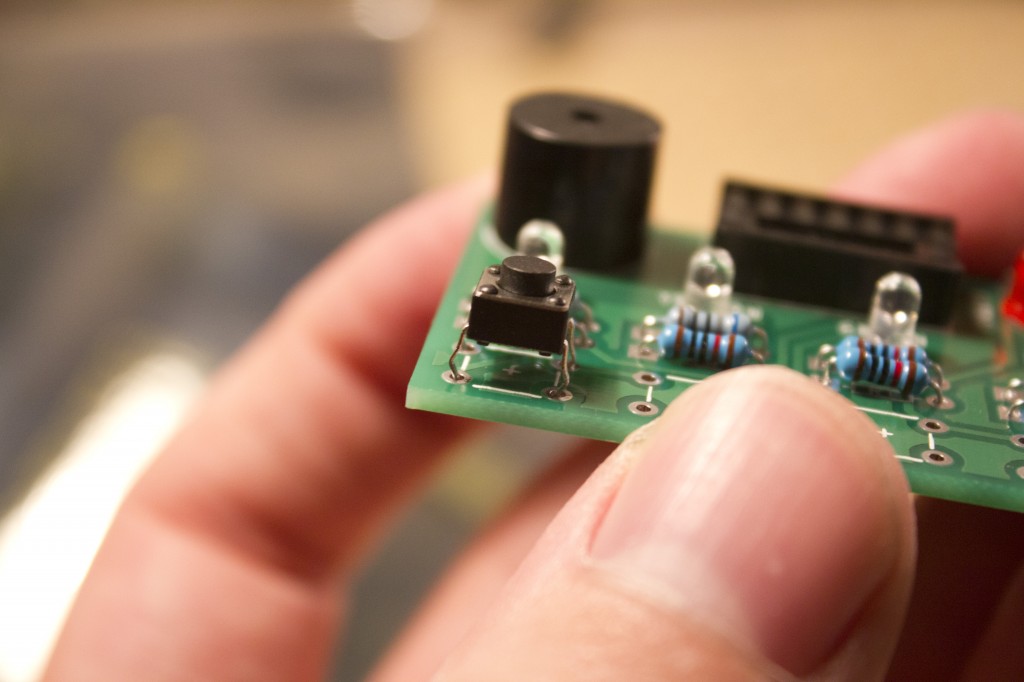

We are now going to add the red power LED. Note that LEDs are polarized and must be inserted correctly in order to work properly. If you look at your LED, you will notice that one lead is shorter than the other. The longer lead will go into the square hole, and the shorter lead will go into the round hole.

If you look even more closely at the LED itself, you should notice that the side with the short lead is slightly flat, and lines up with the white silkscreen on the PCB.

Bend the leads in order to help the LED stay in place while upside down. If this doesn’t work, then you can use tape, or use your hand to carefully press it against the PCB while also holding solder in place like so:

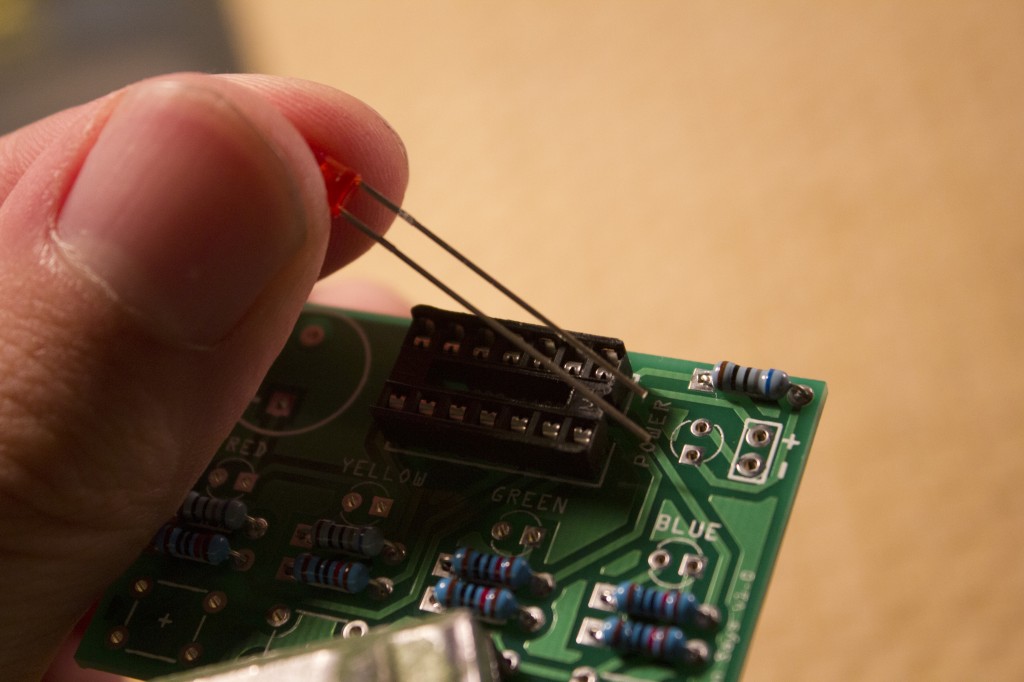

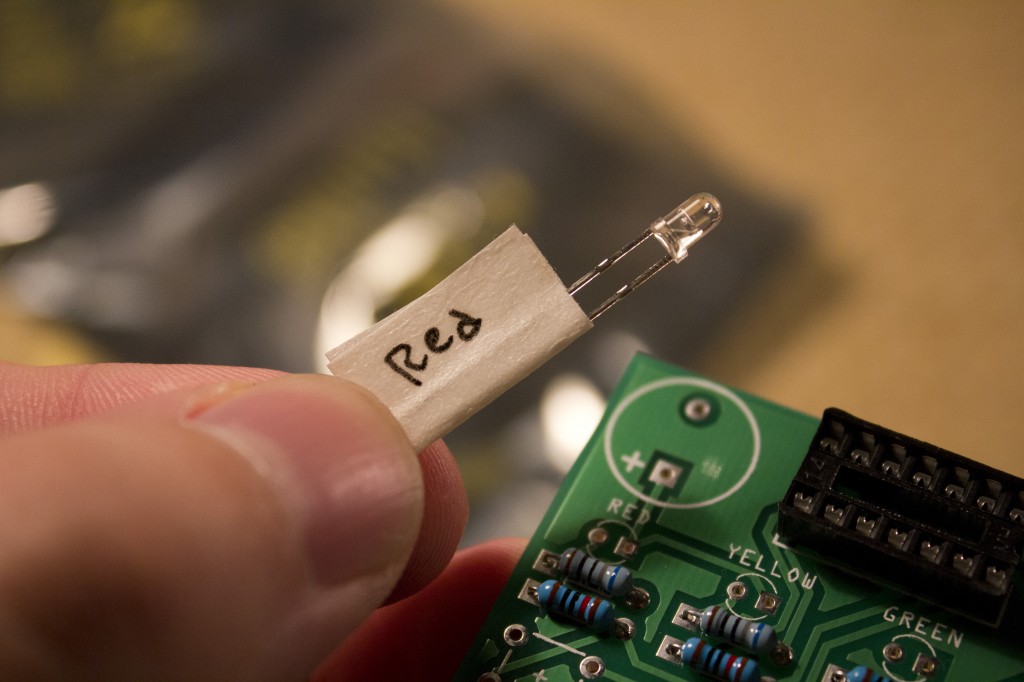

Time to add the rest of the LEDs. Each LED in your kit should be labeled. Because the LED have a clear lens, is recommended that you keep the labels on until you are ready to solder them in place.

Like the power LED, the shorter lead of the LED (the cathode) will go into the round hole, while the longer lead (the anode) will go into the square hole. Solder all of the remaining LEDs in their respective spots on the PCB.

On the piezo buzzer, there is a small “+” symbol. Line it up with the plus symbol on the PCB to ensure that you are inserting it properly. The buzzer will not work if it is inserted backwards.

To hold the buzzer in place, you might be able to get away with fitting it in your vice with the PCB. If not, use your hands or tape.

We’re almost done! Time to insert the pushbuttons. They should snap into and stay in place very easily. Insert all of the pushbuttons, flip the PCB over, and solder them.

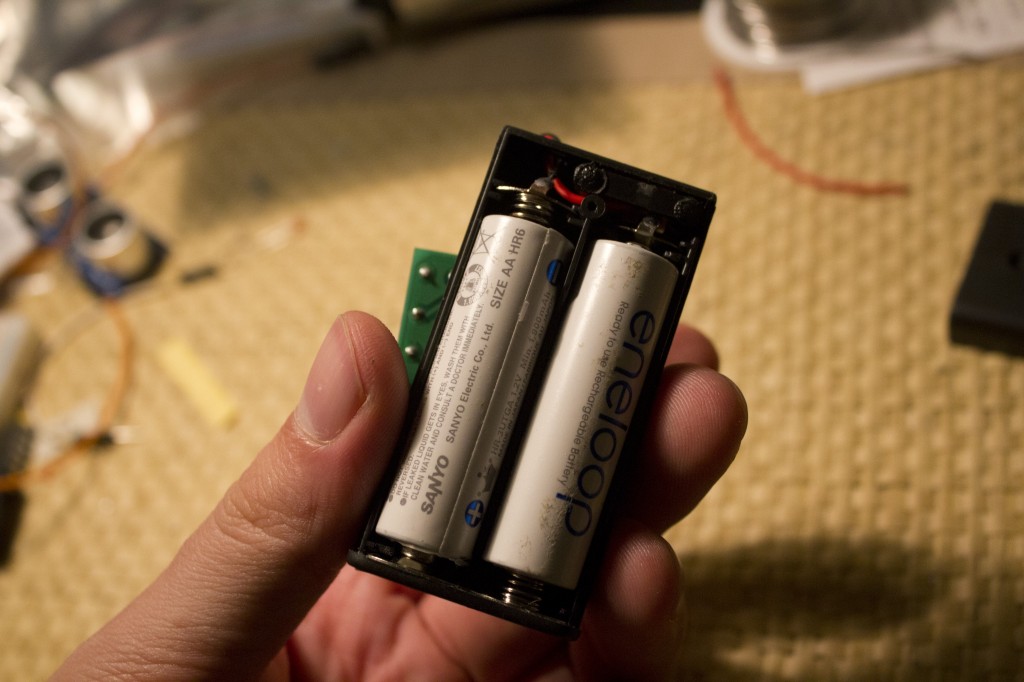

The last item to solder is the leads from the battery pack. Ensure that there are no batteries in the battery pack while soldering it.

Trim the leads of the battery pack to about 4.5cm and strip the ends, leaving about 3mm of wire exposed. Tin the leads with some solder.

Insert the red lead into the “+” hole and solder it. Then insert the black lead into the “-” hole and solder it.

The last thing to do is to insert the microcontroller into the socket. Ensure that you line up the half-circle cutout on the microcontroller with the half-circle cutout on the socket. Failure to insert the microcontroller properly may damage it. The end product should look like this.

Before we stick the battery pack on, test it out! Insert some fresh AAA batteries into the pack and turn the switch on.

The power LED should light up and you should hear the startup noise coming from the buzzer, indicating a new game has started. If the LEDs do not light up, or the buzzer doesn’t work, then double-check all of your solder joints. Also ensure that your batteries are new or charged (if using rechargeable batteries).

The very last step is to peel the plastic off of the piece of double-sided tape on the battery pack and stick the PCB to it.

And with that, you’re done! Congratulations! Remember, this kit is open source. If you want to change the gameplay in any way, you’re absolutely welcome to do so. You can find the source code here along with a small tutorial on how to reprogram the microcontroller using an Arduino (tutorial coming very soon).

Also note, if you don’t want to hear the buzzer tones, just hold down the RED button when you switch the game on and it will start up in silent mode.

Arduino Day @ ISSH at Arduino Praxis

Build Instructions: Simon Says Game Kit v2.0 | Arduino Projects

Build Instructions: Simon Says Game Kit v2.0 | Murchlabs